VeriFast™ MicroView 4.0

The VeriFast™ MicroView 4.0 is a self-contained process monitor, integrated with Ethernet IP communication allowing the machine/cell PLC to monitor the process variables to capture faults and create alerts. It prevents welding from proceeding if fastener parameters fall outside the established tolerance band, maintaining quality and minimizing defects.

VeriFast™ MicroView 4.0

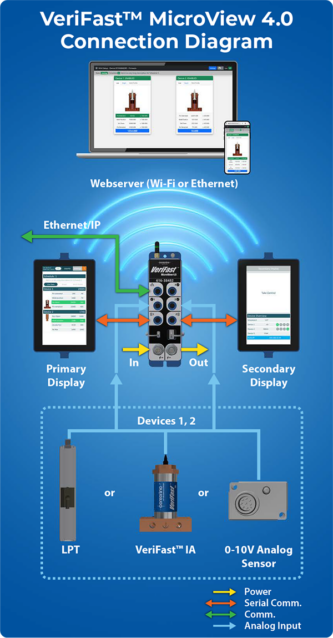

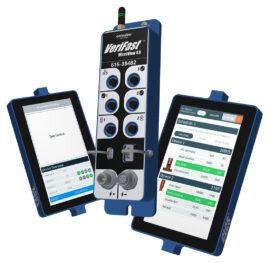

The VeriFast™ MicroView 4.0 process monitor is a self-contained fastener detection system. You simply configure the device using the seven-inch display or a browser via Wi-Fi/Ethernet. Users teach the weld proceed and weld complete setpoints and tolerance bands. The MicroView 4.0 supports two displays: one can be mounted on the machine and the other on the cell fence for remote teaching and monitoring. It has two levels of password protection: Level 1 teaching and Level 2 configuration to prevent untrained personnel from tampering with the process monitoring. The MicroView 4.0 has integrated Ethernet IP communication, allowing the machine/cell PLC to monitor the process variables to capture faults and create alerts. Installation of the IP67 rated block is simple, connect a smart pin sensing weld body and the backup electrode LPT analog devices, 24VDC power and Ethernet IP communication cable. No fastener detection PLC logic or HMI screen development is required.

Why use a VeriFast™ MicroView 4.0?

What is different from MicroView 1.0?

| Feature | MicroView 4.0 | MicroView 1.0 |

|---|---|---|

| Touch HMI | 2 x 7” Capacitive High-Resolution Display | 4.3” Resistive Display |

| Sampling Rate reading per channel | 1000 sps | 800 sps |

| Analog Inputs | Two analog (16 bits resolution) | Two analog (16 bits resolution) |

| Schedules Available | 127 | 16 |

| Output | Ethernet IP communication | Hardwired and connectorized versions available |

| (5 PNP outputs per channel) | ||

| Wi-Fi | IEEE 802.11b, IEEE 802.11g, IEEE 802.11n | N/A |

| WPA/WPA2 Security | ||

| OTA and Webserver | Yes | N/A |

| Simplified Wiring | 6 cords (4 in 2 out), 2 screens, 2 devices, Ethernet IP and 24 V power | Complex Wiring |

| Password Protection | 2 Levels (Operator and Maintenance) | 2 Levels (Operator and Maintenance) |

| Scalable Values | Counts / mm/ inch | Counts / mm/ inch |

| Onboard Storage per Channel | 500k readings | 500k readings |

| Enclosure | IP67 rated | IP67 rated |

| Output | Ethernet IP communication | Hardwired and connectorized version |

| (5 PNP outputs per channel) |