CenterPoint™

CenterPoint™ is a production monitoring system that offers real-time machine status through standardized dashboards, notifications, and reports. This newly incorporated IIoT technology, part of our CenterLine product family, reduces the dependency on manual tracking for equipment performance. The dashboards, designed to match specific equipment, ensure clarity and precision in the data presented.

CenterPoint™ can be utilized as a standalone solution or supplement MES software, delivering paper-free reporting for enhanced efficiency. Automated reporting provides consistent and reliable performance data, offering unbiased insights that validate operator feedback.

CenterPoint™ drives efficiency in your processes by using alerts to identify problems, allowing you to focus your efforts where they matter most. Without the need for additional software training, CenterPoint™ delivers actionable insights based on process-related data trends. This approach highlights necessary actions to improve equipment performance and identifies potential issues before they impact throughput.

CenterPoint™ utilizes manage by exception monitoring to keep your team aware of critical machine issues in real-time, minimizing the impact of production and process-related problems. Reports include metrics such as part counts, scrap counts, and downtime summaries, which can supplement existing systems to maintain accurate inventory levels. Historical production data in CenterPoint™ supports continuous improvement initiatives and informed business decisions. Preconfigured equipment from CenterLine eliminates the need for IT and controls support to monitor, store, and analyze key process-related data from complex equipment.

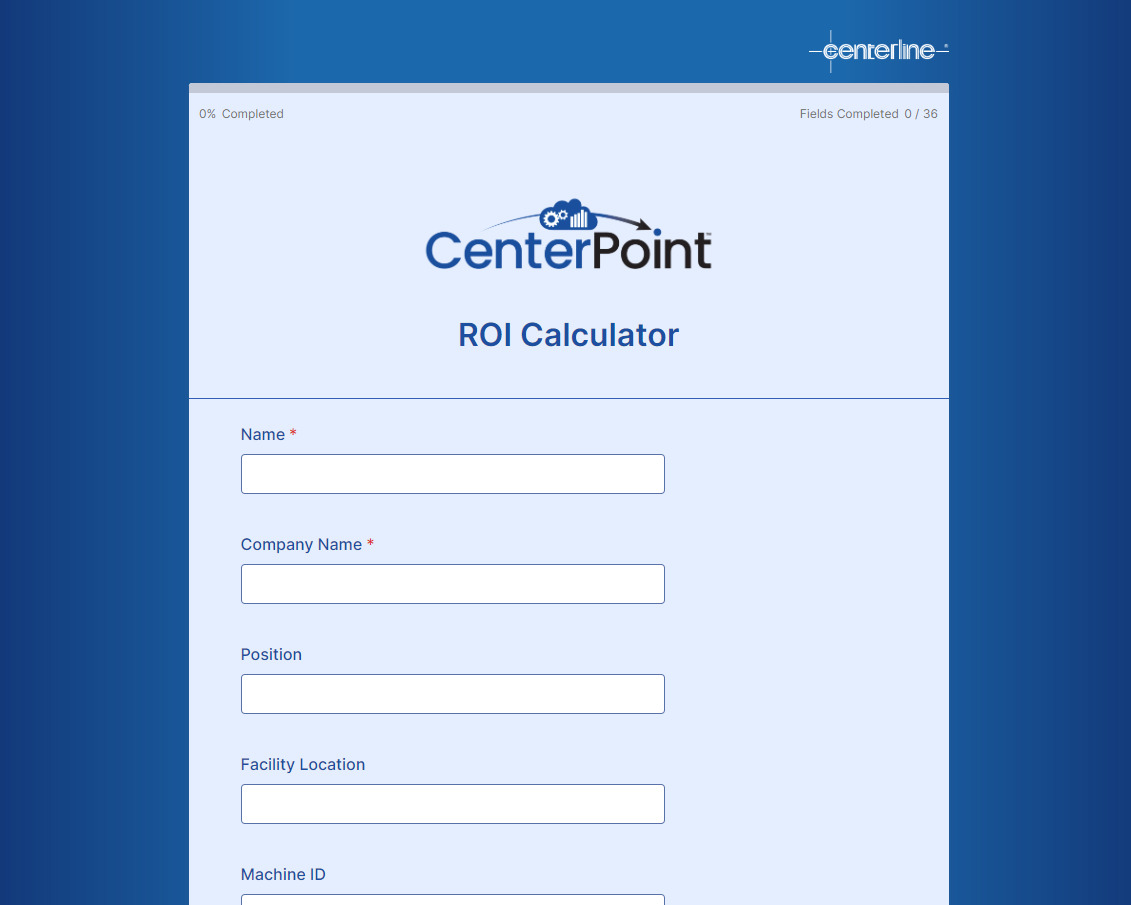

Find out how much ROI CenterPoint™ can give you by trying our CenterPoint™ ROI Calculator for our FlexFast™ machines.

Process Monitoring

Operations Monitoring

Process Monitoring

Operations Monitoring

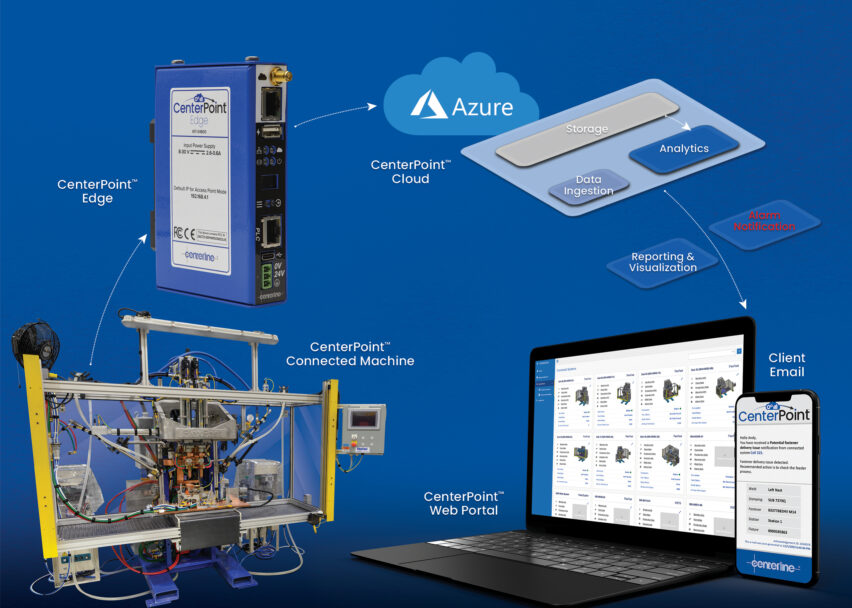

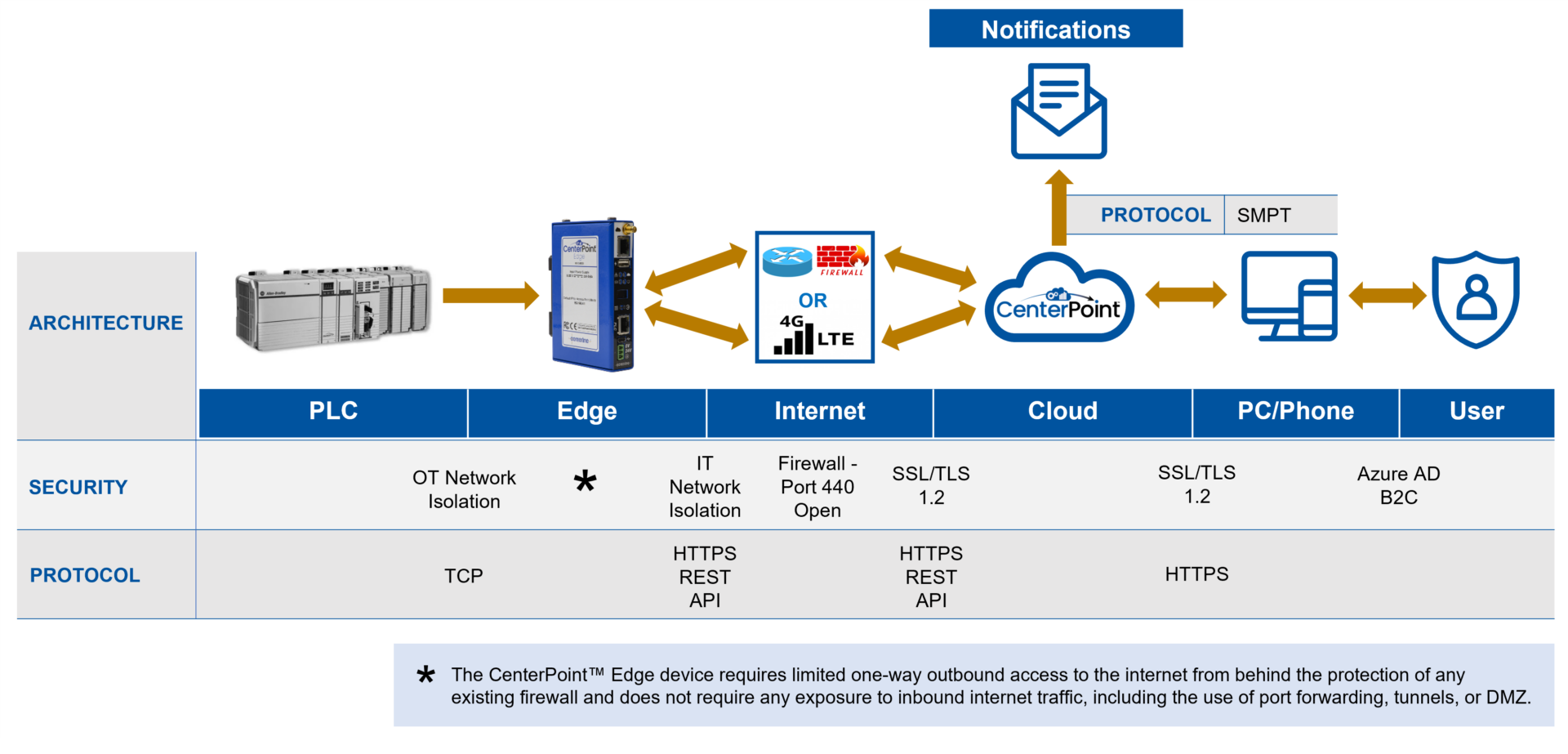

System Architecture

CenterPoint™ uses an Edge device as a “Data Diode” to securely transmit machine data to our cloud-based platform for analysis. This ensures that data flows outward from the PLC, keeping all process adjustments under the control of your team of experts.

Preparing for ISO 27001 Certification in 2024

We are actively working towards obtaining ISO 27001 certification in 2024 to further solidify our commitment to information security. Having achieved SOC2 Type 1 in 2021, we continue to prioritize safeguarding your valuable data. ISO 27001, an internationally recognized standard for information security management systems, will ensure we maintain the highest levels of security across our operations.

Preparing for ISO 27001 Certification in 2024

We are actively working towards obtaining ISO 27001 certification in 2024 to further solidify our commitment to information security.

Having achieved SOC2 Type 1 in 2021, we continue to prioritize safeguarding your valuable data. ISO 27001, an internationally recognized standard for information security management systems, will ensure we maintain the highest levels of security across our operations.

CenterPoint™ Hardware

Edge Device

CenterPoint™ Hardware

Edge Device