PinPoint™ Solution

CenterLine’s patented PinPoint™ Solution is a unique product supplied as a configurable solution to feed parts into robotic lines and cells. The PinPoint™ Solution is designed to maximize production throughput, optimize operator utilization and part flexibility. The standard offering comes with part locating pins, vision part verification and orientation, breakaway part positioning and controls, all in one package.

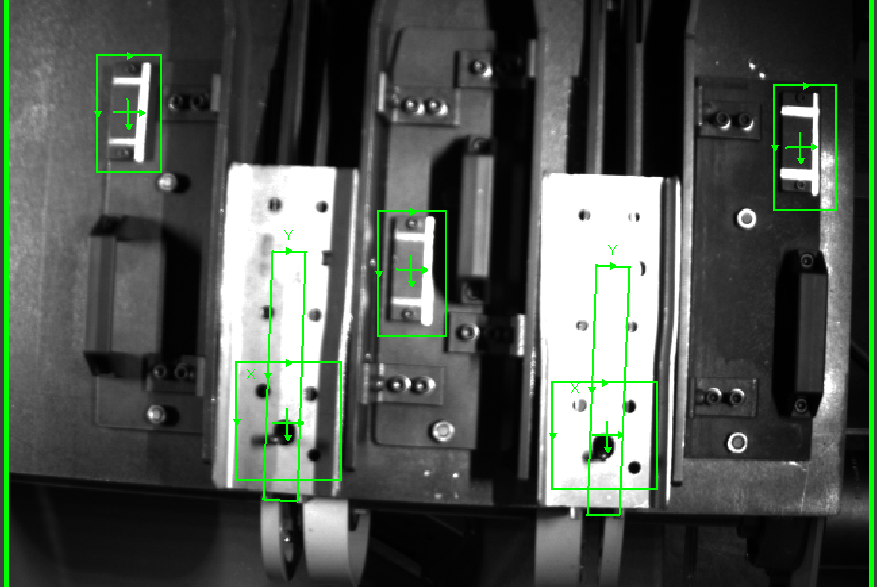

Features