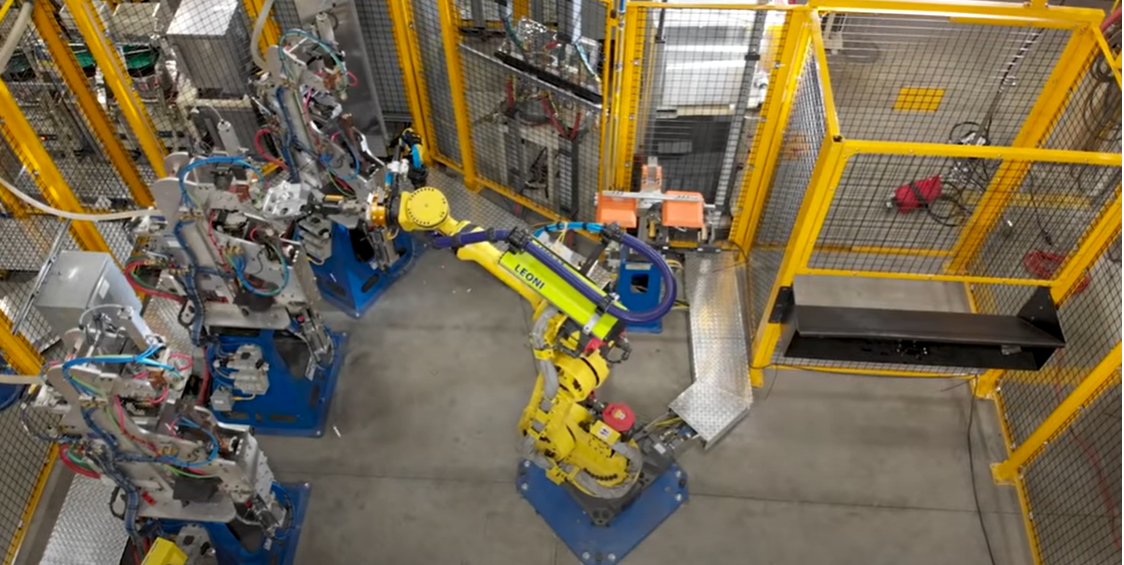

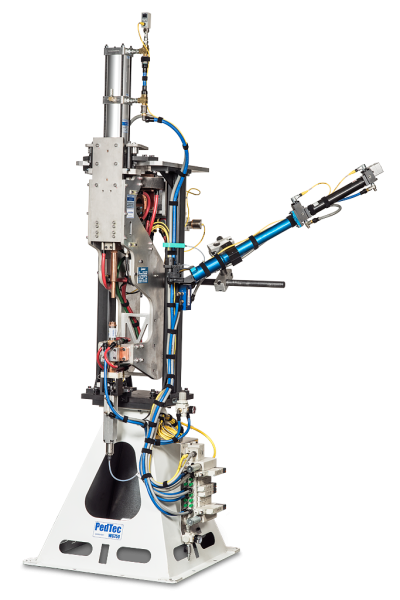

This system is available in two configurations:

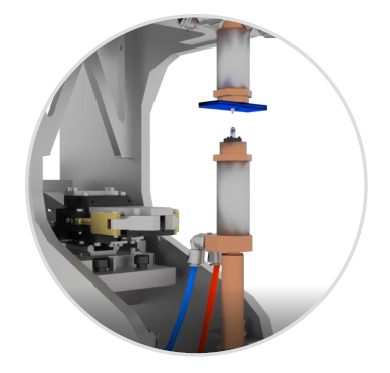

The gun’s compliance feature and the entire gun design have been optimized to create the best balance between stability and ease of movement. The compliance mount assembly is set far enough from the weld plane that it does not introduce variation to the welding process itself.

Key Benefits